CORE COMPETENCIES

Over Five Decades HNB Group has endeavoured to keep up with changing needs of the time while providing technically sound and commercially viable projects.

OVERVIEW

With great Emphasis on Innovation, Leadership and Quality – HNB has consistently delivered successful projects.

EPC PROJECTS

Background:

EPC stands for Engineering, Procurement and Construction (EPC), is a form of contract that undertakes the construction works by the private sector on large-scale infrastructure projects.

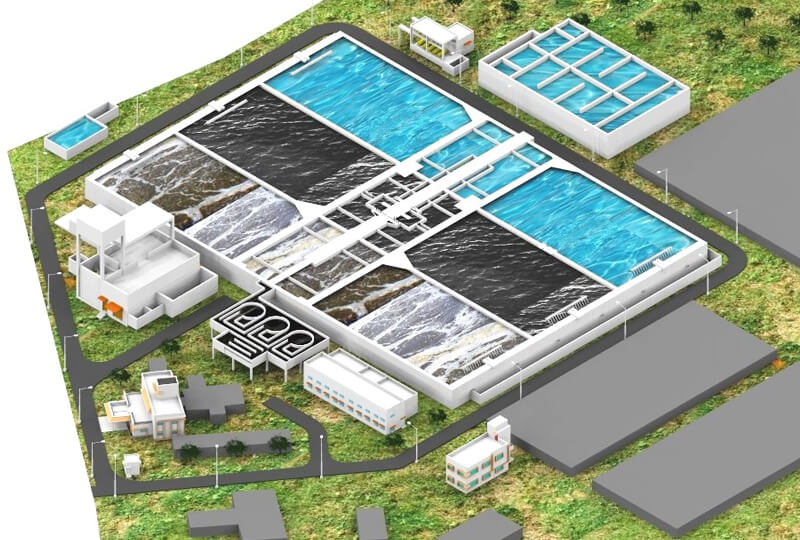

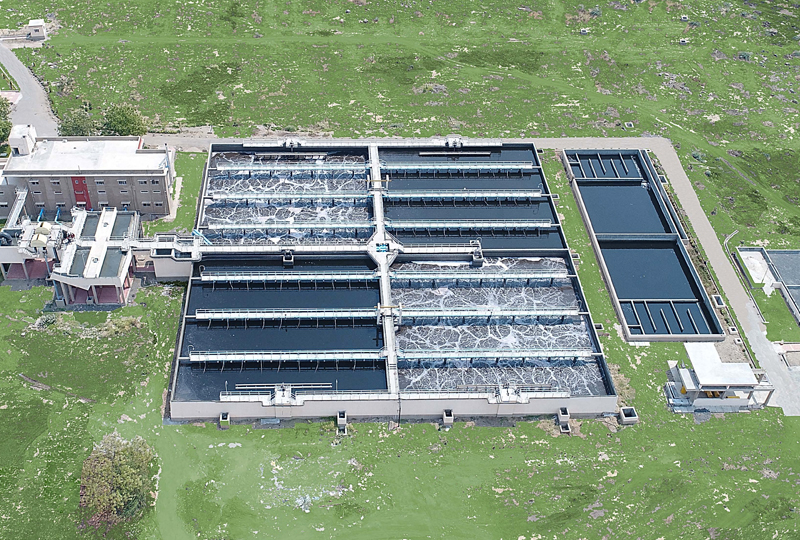

HNB is an EPC contractor engaged in the fields of Water and Waste water Treatment. These kinds of projects usually start with a designing engineering plan, followed by obtaining the materials required for construction, and end with construction of the project. We have in-house capabilities to execute Civil, Mechanical, Electrical and Instrumentation works. In EPC contract we coordinate all design, procurement and construction work and ensure that the whole project is completed in a time bound manner with highest standards of quality.

In EPC contracts we cover the following issues:

Engineering Functions

Basic Engineering

Detailed Engineering

Planning

Construction Engineering

Construction Functions

Electrical Engineering

Mechanical Engineering

Civil Engineering

Procurement Functions

Receiving

Procurement

Invoicing

Purchasing

Commissioning Functions

Automation Services

After-Sales Services

Testing and Commissioning

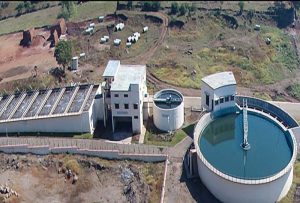

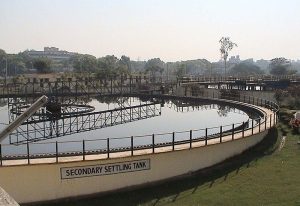

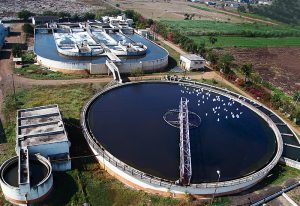

We are very proud to state that we have installed many Sewage Treatments Plants ranging from 100KLD to 100 MLD capacity as an EPC contractorin the last FIVE DECADES. These Plants are running successfully and delivering excellent results.

Why HNB ?

We developed specialized expertise in delivering EPC contracts.

We have in-house capabilities to offer all activities ranging from Design, Procurement, Construction up to Commissioning of the project.

We have demonstrated of proven track record of successfully delivering projects on time with highest standards of quality.

Our Projects are “Turn-Key” type projects which signifies that our clients get a fully completed project that can be put into operation with the simple turn of a key.

PPP PROJECTS

Background:

PPP stands for Public Private Partnership, which means an arrangement between a Government / statutory entity / Government owned entity on one side and a private sector entity on the other, for the provision of public assets and/or public services, through investments being made and/or management being undertaken by the private sector entity, for a specified period of time, where there is well defined allocation of risk between the private sector and the public entity and the private entity who is chosen on the basis of open competitive bidding, receives performance linked payments that conform (or are benchmarked) to specified and pre-determined performance standards, measurable by the public entity or its representative.

Public Private Partnership – Project means a project based on a contract or concession agreement between a Government or statutory entity on the one side and a private sector company on the other side, for delivering an infrastructure service on payment of user charges.

The Features of PPP/Hybrid Annuity Model (HAM):

As per the design, the government will contribute to 40% of the project cost in the first five years through annual payments (annuity).

The remaining payment will be made on the basis of the assets created and the performance of the developer.

Here, hybrid annuity means the first 40% payment is made as a fixed amount in five equal installments whereas the remaining 60% is paid as variable annuity amount after the completion of the project depending upon the value of assets created.

As the government pays only 40%, during the construction stage, the developer should find money for the remaining amount. Here, he has to raise the remaining 60% in the form of equity or loans.

The private developer will recover his investment from the government by receiving annuity payments over a period of 15 years.

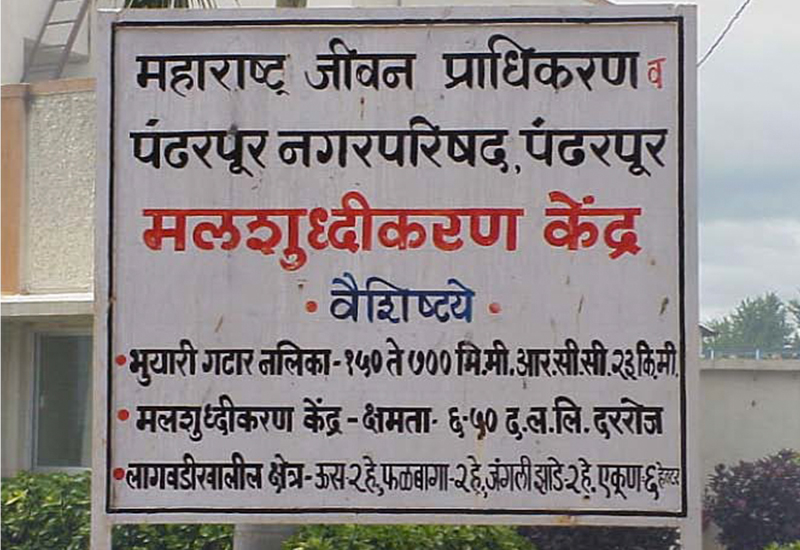

We are the first ever Concessionaire in India who has completed the construction of 82 MLD STP at Haridwar, Uttarakhand (68 MLD STP at Jagjeetpur & 14 MLD STP at Sarai) on PPP / HAM Model. 68 MLD STP at Jagjeetpur was inaugurated by Hon. Prime Minister of India & 14 MLD STP at Sarai was inaugurated by Majesty King of Sweden.

Why HNB ?

We are the first ever Concessionaire in India to have completed and commissioned STP under PPP/HAM model.

We are responsible for delivering truly working assets to our clients.

We have in-house capabilities to offer all activities ranging from Design, Procurement, Construction up to Commissioning of the project. We have deep expertise in Financing of PPP Projects.

We have demonstrated of proven track record of successfully delivering PPP projects on time with highest standards of quality.

Our Projects are “Turn-Key” type projects which signifies that our clients get a fully completed project that can be put into operation with the simple turn of a key.

TECHNOLOGY PROVIDER

Background:

HNB is Technology Provider engaged in the fields of Waste water Treatment and reuse.

We are very proud to state that we introduced SBR technology to India and Implemented it successfully at the first of its kind plant in India of 12.5 MLD capacity, located at Panji (Goa). Since then, we have installed many plants ranging from 100KLD to 100 MLD capacity on our indigenously designed SBR Technology as a Technology Provider. These Plants are running successfully and delivering excellent results.

We are also Technology Providers for the first ever Sewage Treatment Project on Hybrid Annuity Model (HAM)/ Public Private Partnership (PPP) project in India.

We provide technology tie-ups for following types of works:

A. Sequential Batch Reactor

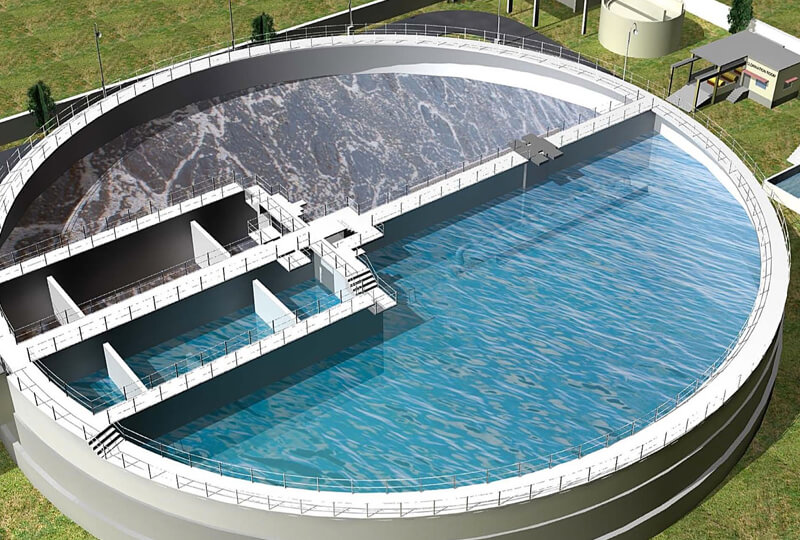

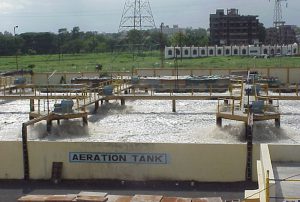

SBR is an abbreviation for SEQUENTIAL BATCH REACTOR process. It provides very high treatment efficiency in a single step biological process. SBR – System is operated in a batch reactor mode, which eliminates all the inefficiencies of the continuous processes. A batch reactor is one which ensures 100% treatment. Two modules of basins are provided to ensure continuous treatment and make the plant’s capacity scalable. This process is purely aerobic.

The complete process takes place in a single reactor, within which all biological treatment steps take place sequentially. NO additional settling unit / secondary clarifier is required!

The advantages of Sequential Batch Reactor Process are:

Low space requirement: Primary Clarifier, Aeration Tank and Secondary Clarifier are combined in a single unit, hence have a smaller footprint.

Automated Operation because entire system is operated using Programmable Logical Circuit.

Good Outlet Quality BOD< 10 mg/l, TSS< 10 mg/l, COD < 50 mg/l and Biological Nutrient Removal (BNR) facilities for nitrogen and phosphorous.

B. Combitreat Technology:

Combitreat Technology is our indigenously designed solution to upgrade purely aerobic STPs such as those built using Sequential Batch Reactor Technology to make them energy efficient. Combitreat Unit harnesses primary sedimentation and anaerobic digestion to treat a major portion of the organic matter without using any electricity. The Combitreat Unit is a combination of Primary Clarifier, Sludge Digester and Biogas Holder Tank.

Combitreat Technology has two main applications:

To upgrade existing purely aerobic sewage treatment plants in order to make them more energy efficient.

To be built along with new sewage treatment plants in order to make them energy efficient.

We hold a Patent for Combi Treat Technology, which enables very high saving in Power consumption, which occupies very less area that too, without compromising on outlet parameters.

Some of our successful installations in which we have Designed, Supplied, Constructed, Erected Machinery, carried out O&M and completed works as Technology Provider for Combitreat technology are listed separately in Gallery.

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

C. Combitreat Power Generation (to Upgrade Existing aerobic STPs)

Combitreat Technology is our indigenously designed solution to upgrade purely aerobic STPs to make them energy efficient. Combitreat Unit harnesses primary sedimentation and anaerobic digestion to treat a major portion of the organic matter without using any electricity. The Combitreat Unit is a combination of Primary Clarifier, Sludge Digester and Biogas Holder Tank.

Combitreat Technology has two main applications:

To upgrade existing purely aerobic sewage treatment plants in order to make them more energy efficient.

To be built along with new sewage treatment plants in order to make them energy efficient.

Some of our successful installations in which we have Designed, Supplied, Constructed, Erected Machinery, carried out O&M and completed works as Technology Provider for Combitreat technology are listed separately in Gallery.

D. iSBR Brand Sequential Batch Reactor with constant level decanting:

Sequential Batch Reactor (Improved) also known, as iSBR is our indigenously designed Technology. It is sequential batch reactor technology with a special decanting arrangement such that level of sewage in SBR basin is always constant. The system is operated in a batch mode and in sequence, which eliminates all the inefficiencies of the continuous processes. A batch reactor is a perfect reactor, which ensures 100% treatment. Modules are provided to ensure continuous treatment and the flow is distributed by using motorized gates at inlet chamber of basin operated on PLC. The complete process takes place in a single reactor, within which all biological treatment steps take place sequentially. The CLSBR basins are equipped with air blowers, diffusers, Sludge pumps, Decanters, Actuated valves, PLC etc. All cycles are automatically controlled using PLC and display of the same can be seen on computer screen using SCADA software.

Sequential Batch Reactor (improved) is an aerobic process. It can be used as a standalone plant or can be used in combination with Combitreat Technology.

It is highly energy efficient and there is no loss of head in decanting process.

Good Outlet Quality BOD< 5 mg/l, TSS< 5 mg/l, COD < 50 mg/l and Biological Nutrient Removal (BNR) facilities for nitrogen and phosphorous removal.

It is compact and takes up a very small footprint.

As on date, this technology has been used in combination with Combitreat Technology and projects are running successfully at numerous locations. Some of our successful installations in which we have Designed, Supplied, Constructed, Erected Machinery, carried out O&M and completed works as Technology Provider for SBR technology (Improved) are listed separately in Gallery.

E. Improved BioTower – an attached growth process:

Improved Biotower Technology is the modern day manifestation of a trickling filter. It is much more modern and has been developed to cater to sewage of variable quantities and of variable organic loads. Special high surface area media is used to have maximum treatment using minimum space.

As described earlier after primary treatment raw sewage is taken to Improved BIOTOWER, where sewage is spread on packed bed of Plastic/PVC medium where fixed film of microorganism is formed over media. Biological degradation of organic matter present in sewage occurs as trickling sewage comes in contact with biological film formed over plastic media. This method is based on empirical data collected over the years, design curves have been developed for various organic loading and different temperature ranges. About 50 % organic load is removed without use of power.

Advantages of Improved Biotower Technology are:

Very high energy efficiency. 50% less power is required than plants based on SBR technology.

Can easily withstand shock loads.

Easy operation and maintenance. No foaming problems. No recirculation of sludge required. No skilled staff is required.

We hold a Patent for Improved Bio – Tower Technologywhich enables very high saving in Power consumption which occupies very less area that too, without compromising on outlet parameters.

Some of our successful installations in which we have Designed, Supplied, Constructed, Erected Machinery, carried out O&M and completed works as Technology Provider for Improved Biotower technology are listed separately in Gallery.

Why HNB ?

We are the only Technology Providers who are also executing the STPs on Turnkey basis including carrying out their O&M.

We have successfully demonstrated numerous projects on our Technologies that are running successfully all across the country.

Our Technologies use indigenously developed and manufactured equipment that have a high working life and consistent performance.

We have deep experience in providing Technology Tie up to prospective EPC contractors.

ENGINEERING DESIGN SERVICES FOR SEWAGE TREATMENT PLANTS (STP)

In early 1900, domestic wastewater i.e. sewage was generally disposed off either in pits, open ground or on surface water bodies. Due to increase in population and rapid industrialization, urban development took place resulted in accumulation of waste in densely crowded habitation/cluster. In order to protect public health and maintain a good standard of living, it became a necessity to treat domestic wastewater before letting it flow into surface streams.

Wastewater treatment systems consist of collection, transport and treatment of domestic wastewater along with its safe disposal. It thus became necessary to establish centralized as well as decentralized domestic sewage treatment plants. These plants are a vital component of infrastructure planning and development of any community. Much emphasis is now being provided on constructing adequate capacity of high performance sewage treatment plants.

Pollution Control Board has periodically published various guidelines to achieve best possible effluent parameters after treatment at a reasonable cost in an effective manner. Various technologies are developed to cater to sewage treatment needs based on Aerobic, Anaerobic or combination of aerobic/anaerobic process.

We are very proud to state that we have installed many Sewage Treatments Plants ranging from 100 KLD to 100 MLD capacity in the last FIVE DECADES. These Plants are running successfully and delivering excellent results.

Clients We Serve

Pimpri Chinchwad Municipal Corporation (PCMC)

Solapur Municipal Corporation (SMC)

Navi Mumbai Municipal Corporation

Government of GOA, PWD Goa

Uttar Pradesh Jal Nigam (UPJN)

Greater New Okhla Industrial Development Authority

(GNOIDA)

New Okhla Industrial Development Authority (GNOIDA)

Delhi Jal Board (DJB)

Uttarakhand PeyJal Nigam (UKPJN)

Yamuna Expressway Industrial Development Authority

(YEIDA)

Gujrat Urban Development Corporation (GUDC)

Gujarat Water Supply and Sewerage Board (GWSSB)

Ahmedabad Municipal Corporation (AMC)

Karnataka Urban Infrastructure Development and Finance

Corporation (KUIDFC)

Davanagere City Corporation through KUIDFC

Bangalore Water Supply and Sewerage Board

City and Industrial Development Corporation of

Maharashtra Limited

Cental Public Works Department

Pune Municpal Corporation

Namami Gange

ENGINEERING DESIGN SERVICES FOR SEWAGE PUMPING STATIONS (SPS)

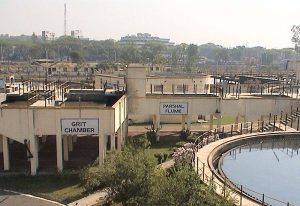

The raw sewage contains mainly organic matters and suspended solids. The organic matter and suspended solids are reduced with the help of microorganisms present in sewage by providing suitable environment for their growth. The organic matter is consumed for the growth of the microorganism’s i.e. Cell production and their metabolism i.e. energy production. The major groups of microorganisms are (i) Aerobic and (ii) Anaerobic microorganisms. In plant treatment, aerobic microorganisms are used for biological treatment.

The raw sewage is collected in the raw sewage sump which is coming through sewer lines by gravity in the inlet chamber. The course screen chamber is provided with SS flat coarse screen. The floating materials and solids are retained on screen which are removed manually/ mechanically and screened sewage is then flows to the raw sewage sump well.

Provision of manual screen is also made in the screen chamber. The raw sewage collected in the sump is pumped to the inlet chamber of pretreatment unit for primary treatment.

We are very proud to state that we have installed many Sewage Pumping Station (SPS) ranging from 5 MLD to 350 MLD capacity in the last FIVE DECADES. These SPS are running successfully.

TERTIARY TREATMENT PLANT (TTP)

Wastewater Treatment and recycle is gaining importance in present scenario of increased water scarcity. Many wastewater treatment plants are being built with water recycle and reuse as main objective. Filtration is one of the important units of tertiary treatment of any wastewater recycle plant primarily to remove suspended solids and associated organics.

OPERATION & MAINTENANCE

Background:

The Scope of Operation and Maintenance includes operating and maintaining all the works and parts of the Sewage Treatment Plant, all interconnecting pipelines and valves, and all other allied works under the Contract complete including the road works, and landscaping, instrumentation systems, Electrical System of Raw Sewage Pumping Station, Sewage Treatment Plant, SCADA systems, all utility and ancillary buildings, etc. and the area of the premises for the entire contract period to the satisfaction of the Client.

Necessary arrangements for plant operation personnel, chemicals usage, lubricants, diesel, spares, tools and tackles, routine maintenance, sewage sampling and sampling and analysis, screenings and grit collection, transportation and disposal, dewatered sludge disposal/sale. Coordination with State Government Body, Local authority, any other authorities and any other activity required for the operation and maintenance of the works/plants in full compliance with all applicable rules, regulations, laws, codes, effluent quality requirements will be arranged by us including the cost of material and labours.

During the Operation and Maintenance period, the stipulated design effluent standards and all performance guaranteed parameters are met in accordance with the specifications in the bid documents and as stipulated in the Performance Guaranteed requirements will be ensured.

Why HNB ?

HNB Engineers has extensive experience in Operation & Maintenance of Sewage Treatment Plants.

Well-trained, qualified and experienced operator with expert supervisors to facilitate smooth day-to-day troubleshooting at operations and maintenance of STP.

We ensure Optimum chemical consumption to maximize efficiency and reduce cost.

We achieve the prescribe norms for treated sewage as prescribed by pollution control board.

We have deep expertise in Preventive maintenance to avoid major breakdown.

RESEARCH & DEVELOPMENT

Our In-house R&D team supports our constant efforts towards innovation & improvement, which facilitates our ability to deliver Turnkey Solutions.