TECHNOLOGY PROVIDER

Background:

HNB is Technology Provider engaged in the fields of Waste water Treatment and reuse.

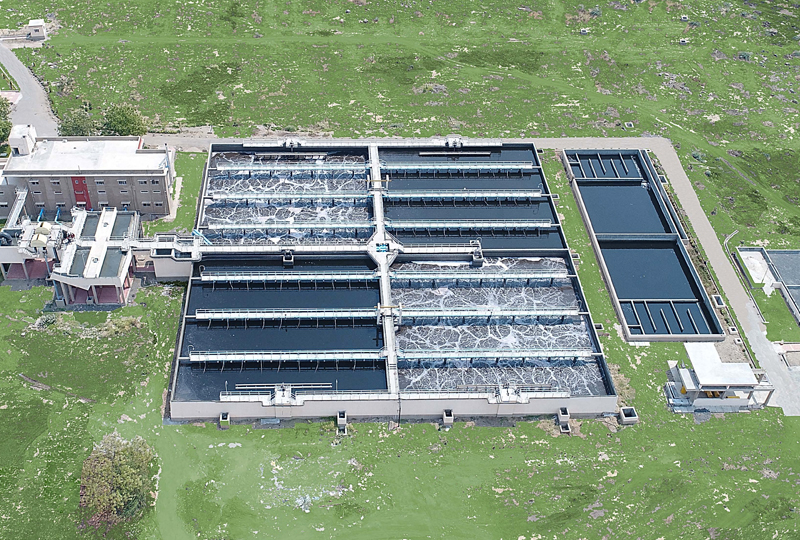

We are very proud to state that we introduced SBR technology to India and Implemented it successfully at the first of its kind plant in India of 12.5 MLD capacity, located at Panji (Goa). Since then, we have installed many plants ranging from 100KLD to 100 MLD capacity on our indigenously designed SBR Technology as a Technology Provider. These Plants are running successfully and delivering excellent results.

We are also Technology Providers for the first ever Sewage Treatment Project on Hybrid Annuity Model (HAM)/ Public Private Partnership (PPP) project in India.

We provide technology tie-ups for following types of works:

A. Sequential Batch Reactor

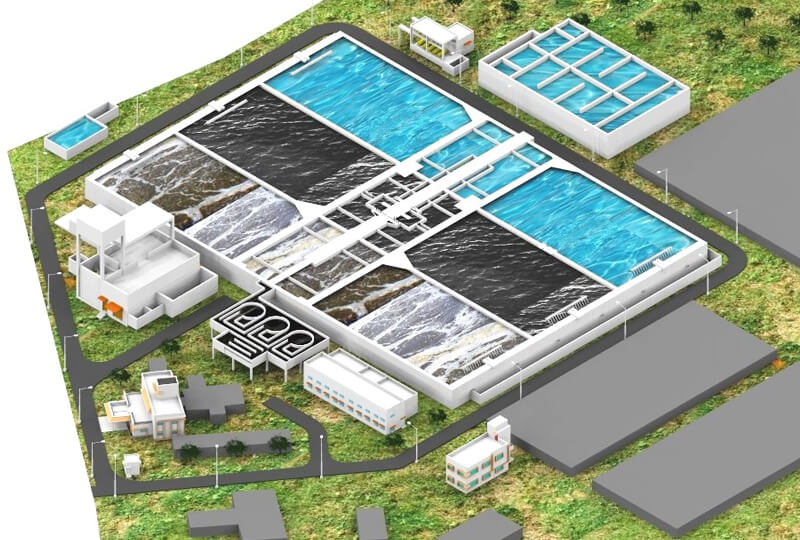

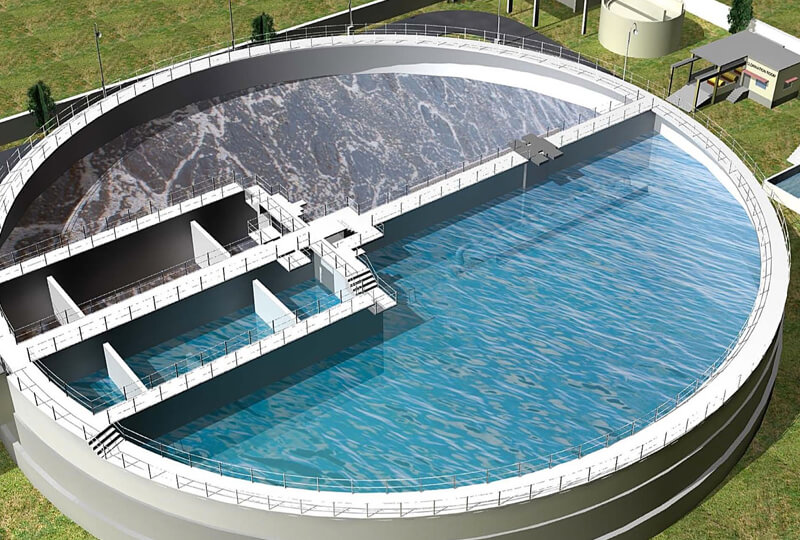

SBR is an abbreviation for SEQUENTIAL BATCH REACTOR process. It provides very high treatment efficiency in a single step biological process. SBR – System is operated in a batch reactor mode, which eliminates all the inefficiencies of the continuous processes. A batch reactor is one which ensures 100% treatment. Two modules of basins are provided to ensure continuous treatment and make the plant’s capacity scalable. This process is purely aerobic.

The complete process takes place in a single reactor, within which all biological treatment steps take place sequentially. NO additional settling unit / secondary clarifier is required!

The advantages of Sequential Batch Reactor Process are:

- Low space requirement: Primary Clarifier, Aeration Tank and Secondary Clarifier are combined in a single unit, hence have a smaller footprint.

-

Good Outlet Quality BOD< 10 mg/l, TSS< 10 mg/l, COD < 50 mg/l and Biological Nutrient Removal (BNR) facilities for nitrogen and phosphorous.

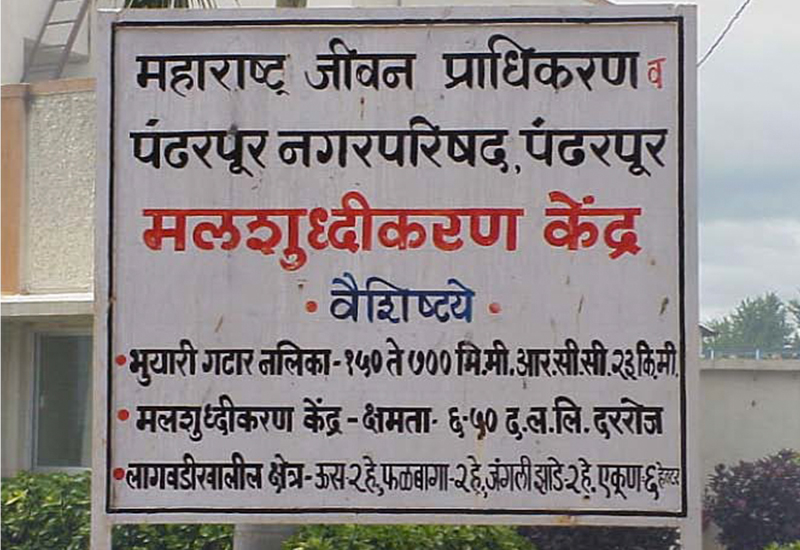

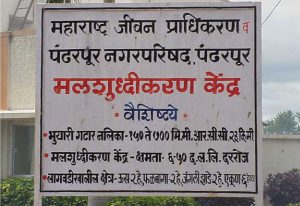

B. Combitreat Technology:

Combitreat Technology is our indigenously designed solution to upgrade purely aerobic STPs such as those built using Sequential Batch Reactor Technology to make them energy efficient. Combitreat Unit harnesses primary sedimentation and anaerobic digestion to treat a major portion of the organic matter without using any electricity. The Combitreat Unit is a combination of Primary Clarifier, Sludge Digester and Biogas Holder Tank.

Combitreat Technology has two main applications:

To upgrade existing purely aerobic sewage treatment plants in order to make them more energy efficient.

To be built along with new sewage treatment plants in order to make them energy efficient.

We hold a Patent for Combi Treat Technology, which enables very high saving in Power consumption, which occupies very less area that too, without compromising on outlet parameters.

Some of our successful installations in which we have Designed, Supplied, Constructed, Erected Machinery, carried out O&M and completed works as Technology Provider for Combitreat technology are listed separately in Gallery.

Your content goes here. Edit or remove this text inline or in the module Content settings. You can also style every aspect of this content in the module Design settings and even apply custom CSS to this text in the module Advanced settings.

C. Combitreat Power Generation (to Upgrade Existing aerobic STPs)

Combitreat Technology is our indigenously designed solution to upgrade purely aerobic STPs to make them energy efficient. Combitreat Unit harnesses primary sedimentation and anaerobic digestion to treat a major portion of the organic matter without using any electricity. The Combitreat Unit is a combination of Primary Clarifier, Sludge Digester and Biogas Holder Tank.

Combitreat Technology has two main applications:

To upgrade existing purely aerobic sewage treatment plants in order to make them more energy efficient.

To be built along with new sewage treatment plants in order to make them energy efficient.

Some of our successful installations in which we have Designed, Supplied, Constructed, Erected Machinery, carried out O&M and completed works as Technology Provider for Combitreat technology are listed separately in Gallery.

D. iSBR Brand Sequential Batch Reactor with constant level decanting:

Sequential Batch Reactor (Improved) also known, as iSBR is our indigenously designed Technology. It is sequential batch reactor technology with a special decanting arrangement such that level of sewage in SBR basin is always constant. The system is operated in a batch mode and in sequence, which eliminates all the inefficiencies of the continuous processes. A batch reactor is a perfect reactor, which ensures 100% treatment. Modules are provided to ensure continuous treatment and the flow is distributed by using motorized gates at inlet chamber of basin operated on PLC. The complete process takes place in a single reactor, within which all biological treatment steps take place sequentially. The CLSBR basins are equipped with air blowers, diffusers, Sludge pumps, Decanters, Actuated valves, PLC etc. All cycles are automatically controlled using PLC and display of the same can be seen on computer screen using SCADA software.

Sequential Batch Reactor (improved) is an aerobic process. It can be used as a standalone plant or can be used in combination with Combitreat Technology.

It is highly energy efficient and there is no loss of head in decanting process.

Good Outlet Quality BOD< 5 mg/l, TSS< 5 mg/l, COD < 50 mg/l and Biological Nutrient Removal (BNR) facilities for nitrogen and phosphorous removal.

It is compact and takes up a very small footprint.

As on date, this technology has been used in combination with Combitreat Technology and projects are running successfully at numerous locations. Some of our successful installations in which we have Designed, Supplied, Constructed, Erected Machinery, carried out O&M and completed works as Technology Provider for SBR technology (Improved) are listed separately in Gallery.

E. Improved BioTower – an attached growth process:

Improved Biotower Technology is the modern day manifestation of a trickling filter. It is much more modern and has been developed to cater to sewage of variable quantities and of variable organic loads. Special high surface area media is used to have maximum treatment using minimum space.

As described earlier after primary treatment raw sewage is taken to Improved BIOTOWER, where sewage is spread on packed bed of Plastic/PVC medium where fixed film of microorganism is formed over media. Biological degradation of organic matter present in sewage occurs as trickling sewage comes in contact with biological film formed over plastic media. This method is based on empirical data collected over the years, design curves have been developed for various organic loading and different temperature ranges. About 50 % organic load is removed without use of power.

Advantages of Improved Biotower Technology are:

Very high energy efficiency. 50% less power is required than plants based on SBR technology.

Can easily withstand shock loads.

Easy operation and maintenance. No foaming problems. No recirculation of sludge required. No skilled staff is required.

We hold a Patent for Improved Bio – Tower Technologywhich enables very high saving in Power consumption which occupies very less area that too, without compromising on outlet parameters.

Some of our successful installations in which we have Designed, Supplied, Constructed, Erected Machinery, carried out O&M and completed works as Technology Provider for Improved Biotower technology are listed separately in Gallery.

Why HNB ?

We are the only Technology Providers who are also executing the STPs on Turnkey basis including carrying out their O&M.

We have successfully demonstrated numerous projects on our Technologies that are running successfully all across the country.

Our Technologies use indigenously developed and manufactured equipment that have a high working life and consistent performance.

We have deep experience in providing Technology Tie up to prospective EPC contractors.